Page 119 - GETELEC catalogue US 2020

P. 119

Conductive metalized fabrics

Conductive metalized fabrics are structures made from polyamide synthetic fibers coated in metal conductive

materials (copper, nickel, silver).These metalized fabrics secured to silicone bases or various foams allow to

produce shielding seals for such applications as information technology, mobile radio, cellular telephony and

other electronic instruments. 4

Applications Formats

- Telecommunication - Cut seals to customer drawing

- Information Technology - Roll

- Automotive

- Medical equipment

- Military…

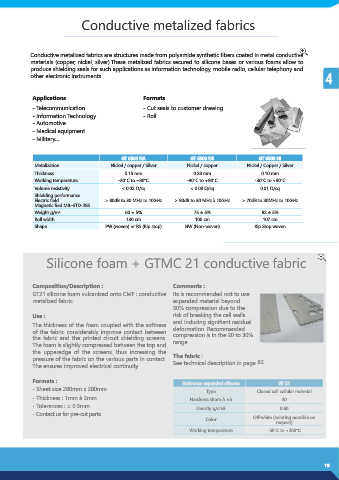

GT 6500 NA GT 6500 NE GT 6500 NI

Metalization Nickel / copper / Silver Nickel / copper Nickel / Copper / Silver

Thickness 0.15 mm 0.28 mm 0.10 mm

Working temperature -30°C to +90°C -30°C to +90°C -30°C to +90°C

Volume resistivity < 0.02 Ω/sq < 0.09 Ω/sq 0.01 Ω/sq

Shielding performance

Electric field > 80dB to 30 MHz to 10GHz > 90dB to 30 MHz à 10GHz > 70dB to 30MHz to 10GHz

Magnetic fied MIL-STD-285

Weight g/m² 60 ± 5% 75 ± 5% 82 ± 5%

Roll width 130 cm 100 cm 107 cm

Shape PW (woven) or RS (Rip stop) NW (Non-woven) Rip Stop woven

Silicone foam + GTMC 21 conductive fabric

Composition/Description : Comments :

GT21 silicone foam vulcanized onto CMF : conductive Its is recommended not to use

metalized fabric. expanded material beyond

50% compression due to the

Use : risk of breaking the cell walls

The thickness of the foam coupled with the softness and inducing signifiant residual

of the fabric considerably improve contact between deformation. Recommanded

the fabric and the printed circuit shielding screens. compression is in the 20 to 30%

The foam is slightly compressed between the top and range.

the upperedge of the screens, thus increasing the

pressure of the fabric on the various parts in contact. The fabric :

The ensures improved electrical continuity. See technical description in page 82.

Formats : Reference expanded silicone GT 21

• Sheet size 280mm x 280mm Type Closed cell cellular material

• Thickness : 1mm à 2mm Hardness shore A ±5 20

• Tolerances : ± 0.3mm Density g/cm3 0.60

• Contact us for pre-cut parts Off-white (coloring possible on

Color

request)

Working temperature -55°C to +200°C

118