Page 81 - GETELEC catalogue US 2020

P. 81

Fluorosilicone

Fluorosilicone products type FVMQ ( ASTM D 1418)

Working temperature : -60°C to +230°C 3

These products have a good resistance to solvents, fuels, organic and silicone oils.

These elastomes are used for the manufacture of molded items, extruded seals, cut flash and seals

vulcanized in place. They maintain their mechanical characteristics over a broad temperature range.

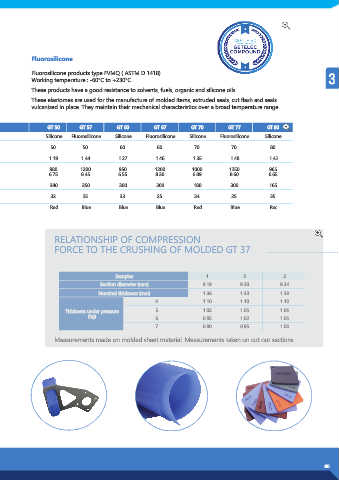

Standards GT 20 GT 30 GT 37 GT 40 GT 47 GT 50 GT 57 GT 60 GT 67 GT 70 GT 77 GT 80

Elastomer binder Silicone Silicone Fluorosilicone Silicone Fluorosilicone Silicone Fluorosilicone Silicone Fluorosilicone Silicone Fluorosilicone Silicone

ASTM D

Hardness shore A (±5) 2240 25 30 30 40 40 50 50 60 60 70 70 80

Specific mass at 25°C (g/cm3) ASTM D 792 1.10 1.11 1.36 1.10 1.43 1.19 1.44 1.27 1.46 1.35 1.48 1.43

Tensile strength 870 980 1000 1000 1250 980 1200 950 1200 1000 1250 965

Psi ASTM D 412 6 6.75 6.90 6.80 8.60 6.75 8.45 6.55 8.30 6.89 8.60 6.65

Mpa

Elongation % ASTM D 412 950 850 480 500 400 380 350 300 300 180 300 165

Residual deformation after 22 ASTM D 395 32 25 33 25 34 25 35

hours at 177°C (%) Mehod B 20 20 20 30 20

Color Red White Blue Orange Blue Red Blue Blue Blue Red Blue Red

RELATIONSHIP OF COMPRESSION

FORCE TO THE CRUSHING OF MOLDED GT 37

Samples 1 2 3

Section diameter (mm) 9.19 9.20 9.24

Nominal thickness (mm) 1.36 1.33 1.38

4 1.10 1.10 1.10

Thickness under pressure 5 1.02 1.05 1.06

(kg) 6 0.95 1.02 1.05

7 0.90 0.95 1.00

Measurements made on molded sheet material. Measurements taken on cut out sections.

80