Page 24 - GETELEC catalogue US 2020

P. 24

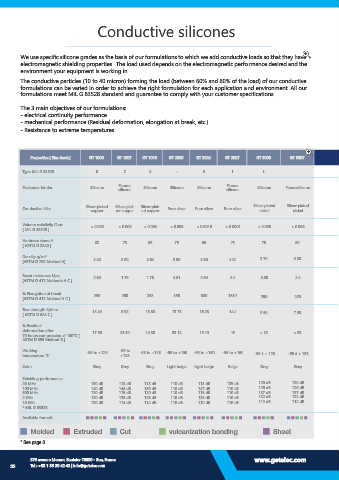

Conductive silicones

We use specific silicone grades as the basis of our formulations to which we add conductive loads so that they have

electromagnetic shielding properties. The load used depends on the electromagnetic performance desired and the

environment your equipment is working in.

The conductive particles (10 to 40 micron) forming the load (between 60% and 80% of the load) of our conductive

formulations can be varied in order to achieve the right formulation for each application and environment. All our

formulations meet MIL G 83528 standard and guarantee to comply with your customer specifications.

The 3 main objectives of our formulations:

- electrical continuity performance

- mechanical performance (Residual deformation, elongation at break, etc.)

- Resistance to extreme temperatures

Properties [ Standards] GT 1000 GT 1007 GT 1015 GT 2020 GT 2024 GT 2027 GT 3000 GT 3007 GT 3100 GT 3107 GT 3300 GT 4000 GT 5000 GT 5007 GT 5080 GT 5087 GT 5200 BL 10000 BL 10007 GT 13100

Type MIL G 83528 K C A - E F L - - - M B D - -

Thermo-

Fluoro- Fluoro- Fluoro- Fluoro- Fluoro- Fluoro-

Elastomer binder Silicone Silicone Silicone Silicone Silicone Fluorosilicone Silicone Silicone Silicone Silicone Silicone EPDM Silicone plastic

silicone silicone silicone silicone silicone silicone

elastomer

Silver- Silver-

Conductive filler Silver-plated Silver-plat- Silver-plat- Pure silver Pure silver Pure silver Silver-plated Silver-plated Nickel Nickel Nickel Silver-plated Silver-plated plated Treated Treated plated Carbon Carbon Nickel

copper ed copper ed copper nickel nickel Graphite Graphite aluminum glass bead aluminum aluminum aluminum Graphite

aluminum aluminum

Volume resistivity Ω.cm < 0.005 < 0.006 < 0.004 < 0.006 < 0.0016 < 0.0006 < 0.005 < 0.006 < 0.10 < 0.10 < 0.5 < 0.015 < 0.0054 < 0.0029 2.5 2.5 < 0.015 2.7 2.7 0.03

[ MIL G 83528 ]

Hardness shore A 82 73 69 75 69 75 75 60 65 65 70 67 65 71 70 80 70 70 73 55

[ ASTM D 2240 ]

Density g/cm 3

[ASTM D 792 Method A] 3.40 3.90 3.64 3.90 3.80 4.30 3.70 3.50 2 2.3 1.88 2 1.90 2 2.5 2.5 2 1.22 1.23 2.34

Break resistance Mpa 2.80 1.79 1.78 4.61 2.64 3.3 3.00 2.4 1.37 1.30 1.73 2.47 1.89 1.85 1.38 1.38 1.70 4.41 6.3 0.50

[ASTM D 412 Methode A C ]

% Elongation at break

[ASTM D 412 Method A C ] 250 250 283 355 380 158.5 290 250 150 200 300 180 286 260 100 / 300 100 / 300 470 200 177.6 200

Tear strength N/mm 13.44 8.92 13.83 13.73 16.28 14.4 9.50 7.50 8.73 6.08 4.70 8.06 8.43 7.36 4.37 4.37 12.00 11.77 21.7 4.10

[ ASTM D 624 C ]

% Residual

deformation after 17.50 25.30 14.30 33.12 15.10 19 < 32 < 35 40 25 30 25 17.30 21 30 30 40 18 18 40

70 hours compression at 100°C [

ASTM D 395 Method B ]

Working -55 to +125 -55 to -55 to +125 -55 to +160 -55 to +160 -55 to +160 -55 à + 125 -55 à + 125 -55 to +150 -55 to +150 -55 to -55 to +160 -55 to +160 -55 to -55 to +160 -55 to -45 to -55 to -55 to +125 -35 to +90

temperature °C +125 +125 +160 +160 +160 +125

Color Grey Grey Grey Light beige Light beige Beige Grey Grey Dark grey Dark grey Grey Grey Grey Light blue Black Black Grey Black Black Grey

Shielding performance:

20 MHz 130 dB 113 dB 113 dB 110 dB 113 dB 125 dB 120 dB 120 dB 100 dB 100 dB 90 dB 118 dB 128 dB 105 dB 80 dB 80 dB 128 dB 60 dB 60 dB 90 dB

100 MHz 140 dB 144 dB 139 dB 110 dB 147 dB 110 dB 126 dB 126 dB 100 dB 100 dB 90 dB 131 dB 137 dB 108 dB 80 dB 80 dB 137 dB 105 dB 60 dB 90 dB

500 MHz 120 dB 119 dB 120 dB 110 dB 118 dB 110 dB 137 dB 137 dB 100 dB 100 dB 90dB 138 dB 133 dB 110 dB 80 dB 80 dB 133 dB 105 dB 60 dB 90 dB

2 GHz 120 dB 128 dB 128 dB 110 dB 128 dB 110 dB 132 dB 132 dB 100 dB 100 dB 90dB 132 dB 122 dB 115 dB 80 dB 80 dB 122 dB 105 dB 60 dB 90 dB

10 GHz 120 dB 114 dB 114 dB 110 dB 110 dB 110 dB 112 dB 112 dB 100 dB 100 dB 90dB 112 dB 104 dB 91 dB 80 dB 80 dB 104 dB 105 dB 60 dB 90 dB

* MIL G 83528

Available formats Injection

Molded Extruded Cut vulcanization bonding Sheet

* See page 8

375 avenue Morane Saulnier 78530 - Buc, France www.getelec.com

23 Tel : +33 1 39 20 42 42 | info@getelec.com