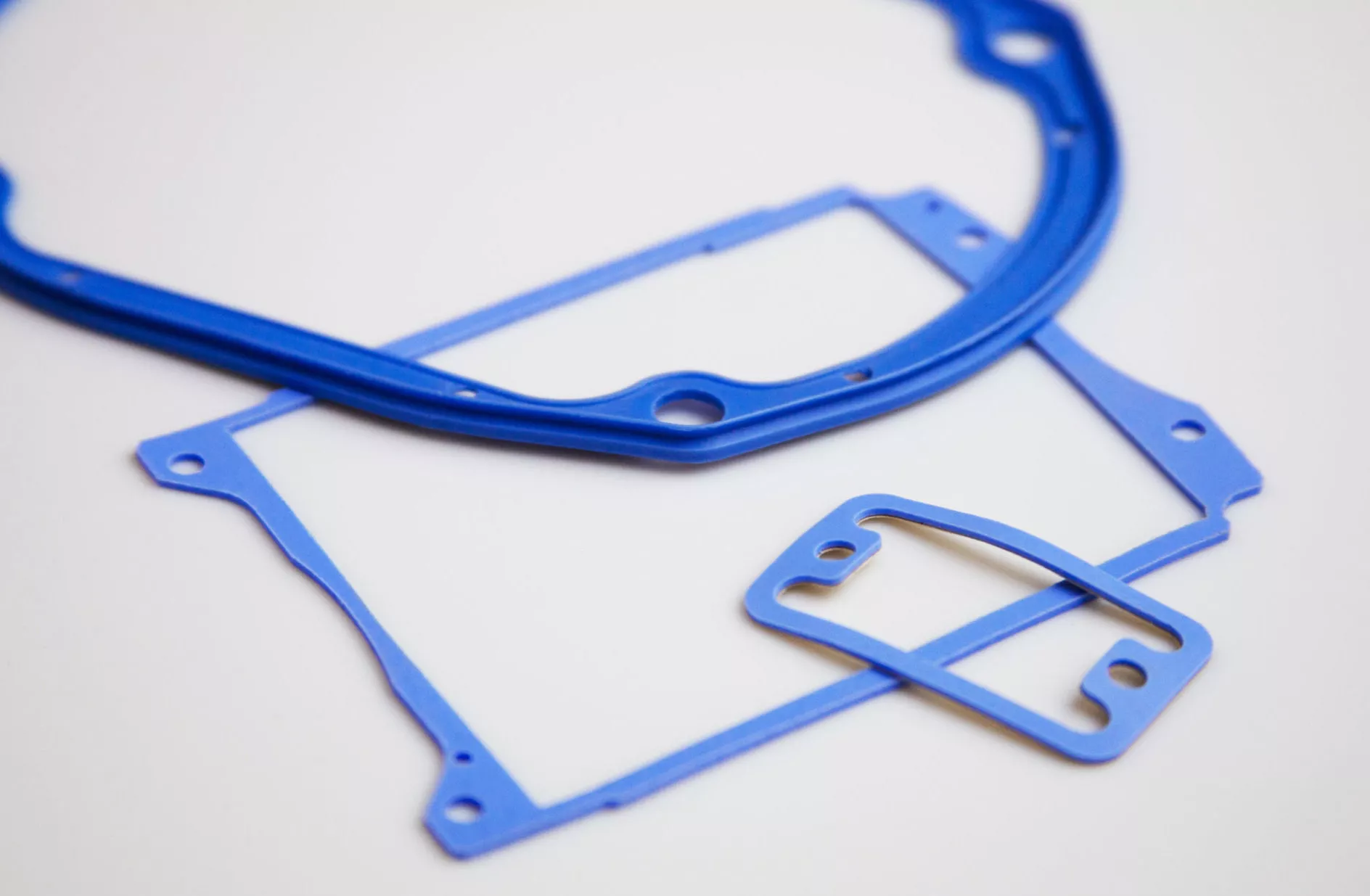

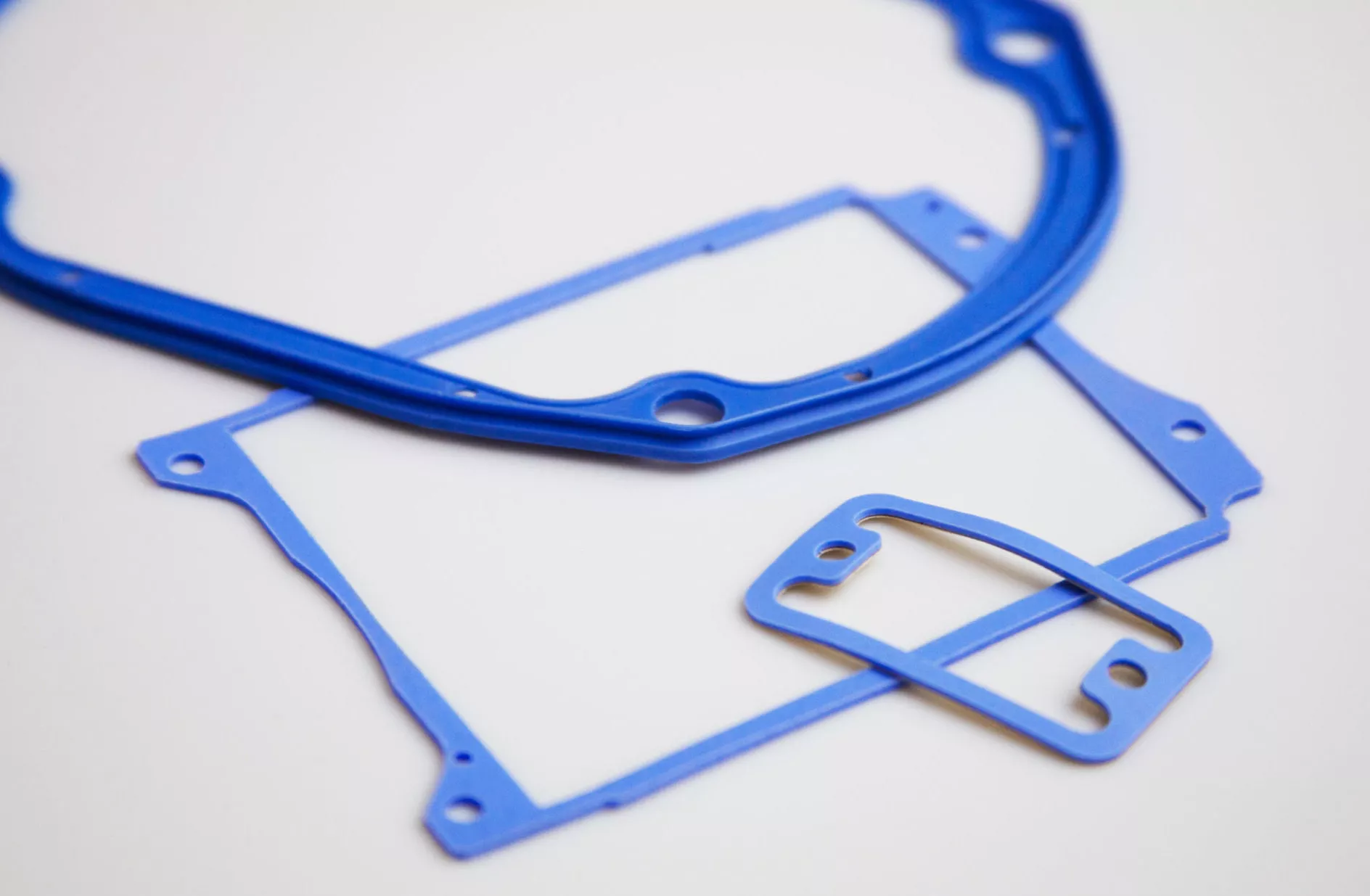

All of our CEM environmentale sealing seals are formulated with specific silicone grades which constitute the core of our formulations. Our R&D laboratory and our design office support you from the selection of the CEM sealing materials to the choice of the transformation process.

Our solutions offer many advantages:

The internal control of the different processes (extrusion, cutting, molding, injection, automatic removal, vulcanization on the cover, etc.) allows us to adapt a tailor-made solution to your environment.

| Properties | Standards - Tests | Silicone range | Fluorosilicone range |

|---|---|---|---|

| Hardness (Shore A) | ASTM D 2240 | 25 to 80 | 30 to 70 |

| Specific mass at 25°C (g/cm3) | ASTM D 792 | 1.10 to 1.43 | 1.36 to 1.48 |

| Tensile strength (Mpa) | ASTM D 412 | 6 to 6.89 | 6.80 to 8.60 |

| Elongation (%) | ASTM D 412 | 165 to 950 | 300 to 480 |

| Residual deformation after compression 22 hours at 177°C (%) | ASTM D 395 Method B | 20 to 35 | 20 to 25 |

All our environmental sealing solutions are available as sheets, extruded profiles, O-rings, moulded or die-cut.

Our know-how and our support policy also includes taking into account your constraints and tolerances, which is why all of our solutions can be made to measure according to your specific plans and manufacturing processes within a short timeframe.