Electromagnetic compatibility (EMC) is an essential feature for all electronic equipment. The function of a electrically conductive elastomer gasket is to maintain electrical continuity in the EMC shielding. The conductive filler used for our conductive silicone seals is adjusted according to the electromagnetic performance required and the environment in which your equipment is located.

The conductive particles (10 to 40 microns) that make up the filler of our conductive mixes (between 60 and 80% filler ratio) allow you to acquire optimal EMC shielding.

Our electrically conductive elastomers are developed in every respect by our chemical engineers. From the selection of raw materials to the final transformation, they create specific formulations for each request and master all the development processes and procedures.

This mastery allows us to define the ideal material according to your equipment and your specifications, in order to offer you a bespoke conductive solution adapted to your needs.

Getelec develops and manufactures silicone- and fluorinated silicone-based conductive solutions filled with conductive particles such as silver-plated copper, silver, silver-plated nickel, graphite nickel, aluminium nickel, silver-plated aluminium, treated aluminium, carbon and silver-plated glass beads to guarantee optimal galvanic and electromagnetic compatibility.

In addition to our conductive mixes, we also offer alternative solutions to some of the known obsolescence in our industries. Our GT1000 and GT5000 EX references are developed from filled elastomers capable of meeting your specific needs.

All our conductive materials meet the requirements of standard MIL STD 83528.

Our know-how and our support policy also includes taking into account your constraints and tolerances, which is why all of our solutions can be made to measure according to your specific plans and manufacturing processes within a short timeframe.

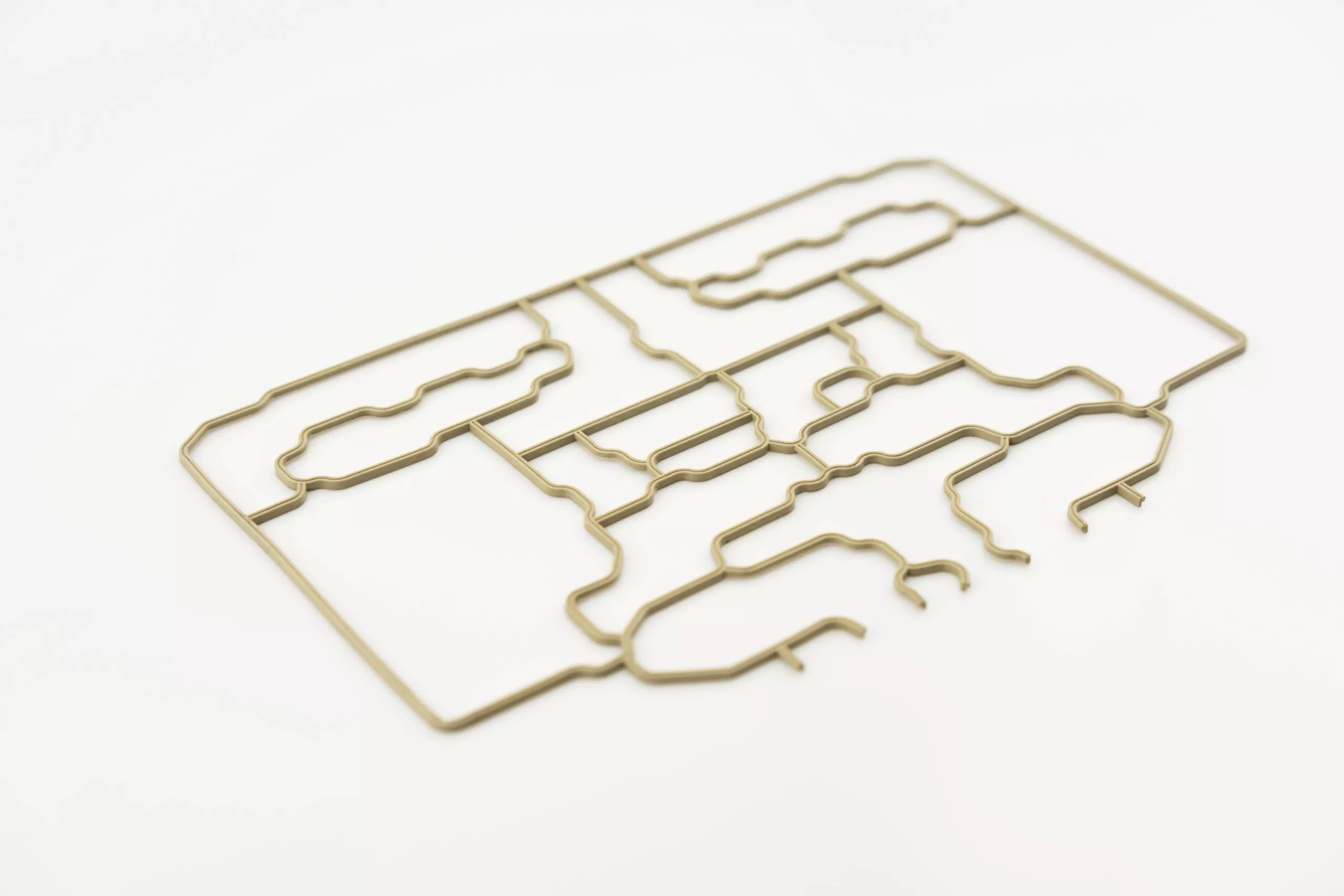

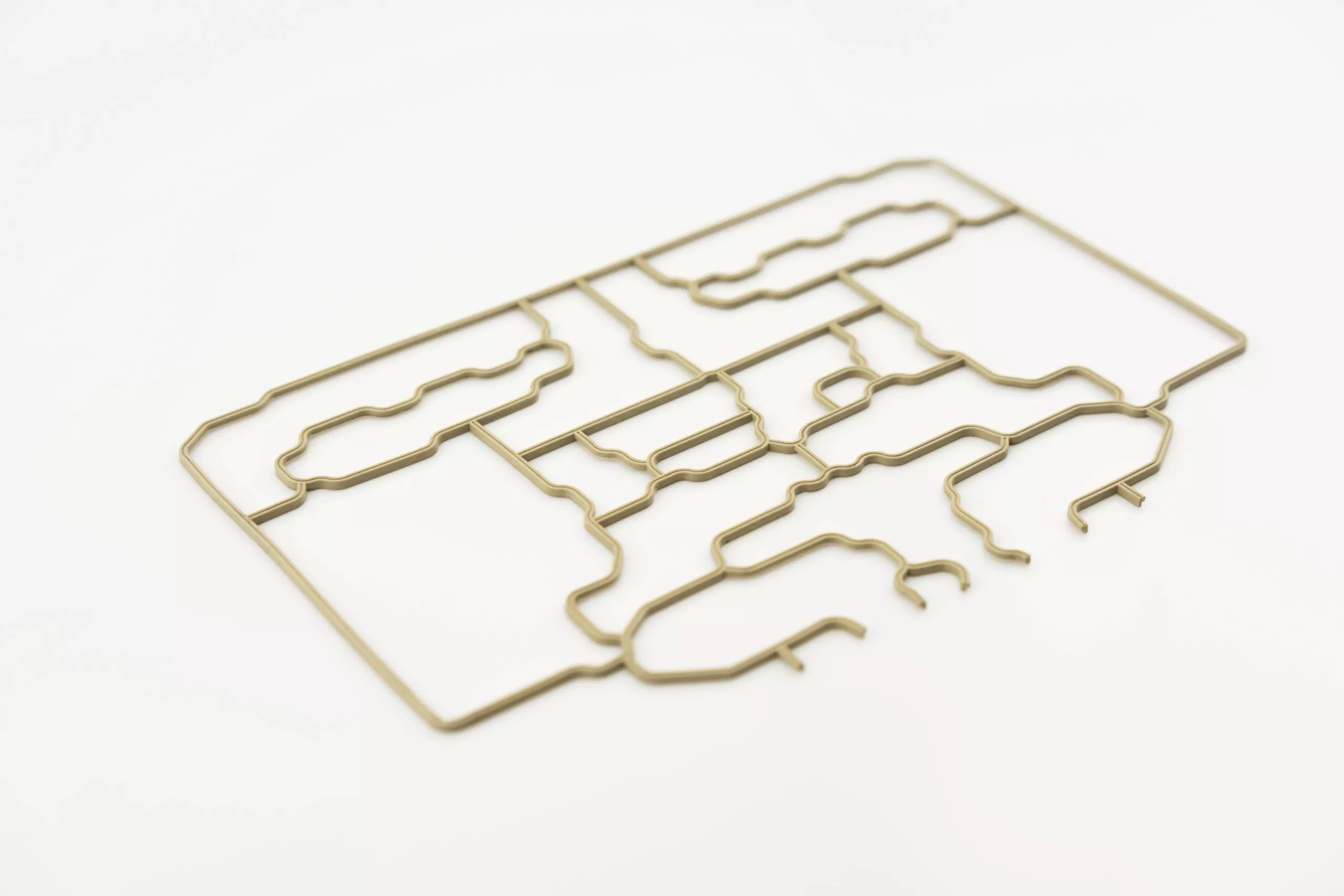

Our materials are also available in a variety of standard formats such as sheets, extruded profiles, O-rings, moulded to shape, die-cut or integrated directly into your equipment.

Our conductive materials have been developed to meet all your multi-sectoral requirements. The compliance of our mixtures with standards: MIL STD 83528 and ESA-ECSS-Q-ST-70-02C allows you to cover all your sectors with the most stringent requirements such as:

| Getelec material reference | elastomer | Conductive filler | Technical sheet |

|---|---|---|---|

| GT1000 | Silicone | Silver-plated copper | PDF sheet |

| GT1000 Flex | Silicone | Silver-plated copper | PDF sheet |

| GT1007 | Fluorosilicone | Silver-plated copper | PDF sheet |

| GT1015 | Silicone | Silver-plated copper | PDF sheet |

| GT2020 | Silicone | Pure silver | PDF sheet |

| GT2024 | Silicone | Pure silver | PDF sheet |

| GT2027 | Fluorosilicone | Pure silver | PDF sheet |

| GT3000 | Silicone | Silver-plated nickel | PDF sheet |

| GT3007 | Fluorosilicone | Silver-plated nickel | PDF sheet |

| GT3100 | Silicone | Nickel Graphite | PDF sheet |

| GT3107 | Fluorosilicone | Nickel Graphite | PDF sheet |

| GT3300 | Silicone | Aluminum Nickel | PDF sheet |

| GT4000 | Silicone | Silver-plated glass bead | PDF sheet |

| GT5000 | Silicone | Silver-plated aluminum | PDF sheet |

| GT5000 FLEX | Silicone | Silver-plated aluminum | PDF sheet |

| GT5000 EX SP | Expanded silicone | Silver-plated aluminum | PDF sheet |

| GT5007 | Fluorosilicone | Silver-plated aluminum | PDF sheet |

| GT5200 | EDPM | Silver-plated aluminum | PDF sheet |

| BL10000 | Silicone | Carbon | PDF sheet |

| BL10007 | Fluorosilicone | Carbon | PDF sheet |

| GT13100 | Thermoplastic elastomer | Nickel Graphite | PDF sheet |